Bridge Metal

Imagine that you were tasked with building a bridge that moved vehicles over a waterway. What metals would you choose to construct your bridge? Your challenge is to test a set of metals to determine which metal should serve as the superstructure for your bridge. I hope that you and your bridge don’t fall apart over this challenge.

What are the characteristics of good bridge-building metals?

Good bridge building metals need to be strong and easy to shape. The material for a bridge must be incredibly strong because not only does it have to hold up its own weight, but it also must withstand the weight of cars and trucks. The metal also has to be durable as the bridge must withstand everyday weather and climate, as well as natural disasters like hurricane force winds or large amounts of snowfall from a blizzard. Iron and steel are used frequently to make not only bridges, but also buildings and ships. The advantages of the use of steel are its incredible strength, flexibility, reliability, abundance, and low cost.What is the Mohs Scale of Hardness?

Mohs Scale of Hardness is a scale of mineral hardness. People use the scale to determine an unknown mineral's hardness. Using a database of the mineral's hardness, it could be used to help identify the unknown mineral. Mohs Scale of Hardness works by knowing that some minerals are harder than others, while some are softer. Based on the hardness, harder materials can scratch softer ones. For example, your fingernail has a hardness of 2.5. Using your fingernail, if you try scratching pencil lead which has a hardness of 1.5, it will be scratched and you will know that the pencil lead has a hardness that is less than 2.5. If you use your fingernail to try scratching a diamond, the hardest mineral of Mohs Scale of Hardness, you will not be able to scratch its surface, so you know diamonds are harder than your fingernail.| Moh's Scale Value | Comparison Mineral | Test Results | |

| 1 | Talc | Fingernail can powder | |

| 2 | Gypsum | Fingernail can scratch (fingernail hardness = 2.5) | |

| 3 | Calcite | Copper coin can scratch (penny hardness = 3) | |

| 4 | Fluorite | Pen knife easily scratches (knife hardness = 5) | |

| 5 | Apatite | Pen knife barely scratches | |

| 6 | Orthoclase | Steel file scratches (file hardness = 6.5) | |

| 7 | Quartz | Scratches glass or steel easily (glass hardness = 5.5) | |

| 8 | Topaz | Easily scratches quartz | |

| 9 | Corundum | Easily scratches topaz | |

| 10 | Diamond | Cannot be scratched |

What is the hardness of a metal?

The hardness of a metal is similar to the hardness of a mineral. Hardness is the resistance of a material to deform or change shape. The deformation is due to the breaking of chemical bonds in the material and displacement of atoms. In metals, instead of just seeing a scratch between two minerals as a test of the hardness of a metal, the indentation is measured in the tested material. In the Brinell Hardness Test, the surface area of the indentation is used to find hardness. In the Rockwell Hardness Test, the depth of the indentation is used to measure hardness.What does the measurement unit MPa represent?

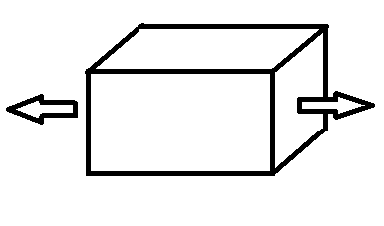

MPa is a megapascal, which is a measurement of pressure commonly used for measuring stiffness or tensile strength. Stiffness is the rigidity of the object and the resistance to deformation. Tensile strength is the maximum stress of being stretched or pulled that a material can withstand. Stress is a force applied over an area.What is tensile strength?

Tensile strength is the ability to withstand being stretched or pulled. If a material experiences too large a tensile force, there will be necking, which is when the material disproportionately contracts in a localized area. For example, Kevlar™ is a material used in body armor, and it has a high tensile strength because it cannot be pulled or stretched apart easily.)

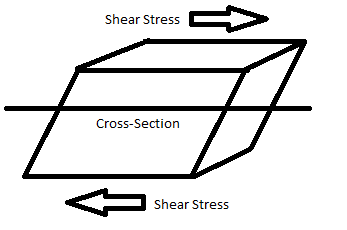

What is shear strength?

Shear strength is the ability to withstand shear stress. Shear stress is the stress that is parallel to the cross section. While tensile strength will just enlarge the rectangular prism, shear stress will cause a change in shape, like from a rectangular prism to a rhombic prism as shown below.)

Walkthrough

Tier 2 Lessons: Grades 7 - 12+

You need to log in to access this simulation.